In 2016, an automotive engineer discovered a critical gap between a wiring harness and an oil line... three weeks before production launch. The cost of the emergency modification: €2.3 million. If only distance band analysis had been used.

Imagine transforming your complex CAD model into an intuitive heat map, where colors instantly reveal all critical gaps. Distance band analysis does just that—it converts abstract numerical measurements into visual signals that anyone can understand at a glance. No more sleepless nights verifying hundreds of measurements, no more interference discovered on the physical prototype.

What if a simple color code could save your next project?

Table of contents

- Understanding band distance analysis in CAD models

- Technical challenges of distance analysis in multi-CAD environments

- Band distance analysis methodologies

- 3DViewStation: optimal solution for band distance analysis

- Practical applications and case studies

- Best practices and analysis optimization

Understanding band distance analysis in CAD models

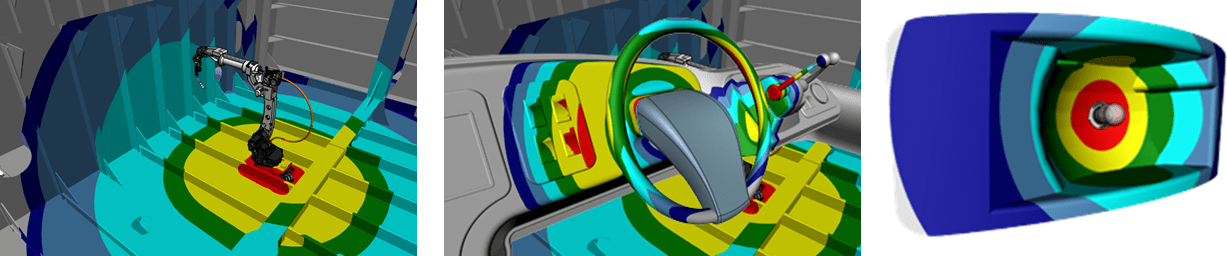

Band distance analysis is an advanced visualization technique that allows for intuitive evaluation of spacing between different elements in a CAD model. Unlike traditional methods that only provide numerical values, this approach codes distances using colored bands, facilitating immediate identification of critical areas without requiring in-depth expertise in 3D design.

This methodology is based on creating colored volumes between components, with each color representing a specific distance range. For example, red zones may indicate spacing less than 5 mm, while green zones signal distances that conform to specifications. This simple yet powerful principle transforms complex numerical data into immediately comprehensible visual information.

Difference from other analysis methods

Band distance analysis fundamentally differs from other spatial analysis techniques such as collision detection or point measurements. Here are the main differences:

- Unlike collision detection which only identifies interferences, band analysis visualizes a complete spectrum of distances

- While point measurements require manual selection of points to measure, band analysis automatically evaluates the entirety of surfaces

- Results are presented as colored volumes rather than simple numerical values, facilitating interpretation

This global approach allows for quickly identifying potential problems that might go unnoticed with conventional methods, especially in complex models comprising thousands of components.

Sectoral applications

| Industrial sector | Typical applications | Key benefits |

|---|---|---|

| Automotive | Verification of spacing in engine compartments | Prevention of thermal and vibratory interferences |

| Aerospace | Analysis of spacing between hydraulic systems and structure | Compliance with strict safety requirements |

| Electronics | Verification of distances between components on PCBs | Prevention of short circuits and thermal optimization |

| Construction | Analysis of spacing for cable passages and piping | Reduction of conflicts during installation |

Technical challenges of distance analysis in multi-CAD environments

Band distance analysis in modern industrial environments faces several major technical challenges, mainly related to the heterogeneity of CAD systems and the increasing complexity of digital models.

Interoperability issues between CAD formats

In an industrial ecosystem where multiple CAD systems coexist (Catia, NX, Creo, SolidWorks, etc.), interoperability represents a significant challenge. Each system uses its own modeling algorithms and native formats, creating substantial obstacles:

- Often imperfect data conversion between proprietary formats

- Potential loss of geometric precision during exchanges

- Assembly structures sometimes altered or simplified

- Metadata and attributes rarely fully preserved

These interoperability problems considerably complicate band distance analysis, as the accuracy of results directly depends on the geometric fidelity of the analyzed models. A high-performing solution must therefore imperatively offer native reading of the main CAD formats to avoid these pitfalls.

Complexity of large 3D models

Technological evolution has led to an exponential increase in the complexity of industrial 3D models. A modern automotive assembly can include more than 20,000 distinct parts, while a complete aircraft can count several million. This complexity generates several challenges:

- Considerable computing resource requirements (memory, processor)

- Potentially prohibitive loading and calculation times

- Difficulties in navigation and interaction within massive models

- Risk of inaccuracies in distance calculations on complex geometries

Band distance analysis solutions must therefore implement advanced technologies for optimization and management of volumetric data to maintain acceptable performance, even on assemblies counting tens of thousands of components.

Precision and reliability of measurements

Band distance analysis is only valuable if its results are accurate and reliable. Several factors can compromise this precision:

- Variable quality of CAD models (presence of degenerated faces, gaps, etc.)

- Mathematical precision of distance calculation algorithms

- Sometimes insufficient level of detail (LOD) of models

- Poorly defined geometric and dimensional tolerance

In sectors where precision is critical, such as aerospace or medical, these considerations take on particular importance and require tools capable of guaranteeing minimal error margins.

Band distance analysis methodologies

Band distance analysis is based on precise mathematical principles and structured methodologies that allow for obtaining reliable and exploitable results. To fully master this technique, it is essential to understand its theoretical and practical foundations.

Underlying mathematical principles

At the heart of band distance analysis are several advanced mathematical concepts:

- Calculation of Euclidean distance between parametric surfaces

- Optimization methods to determine the closest points

- Propagation algorithms to generate band volumes

- Spatial sampling techniques to optimize performance

These algorithms must be both precise and performant, as they will be applied to thousands or even millions of points in a complex CAD model. The robustness of these mathematical foundations directly determines the reliability of the results obtained.

Color band parametrization

The effectiveness of band analysis relies on judicious parametrization of distance ranges and associated colors. This parametrization must be adapted to the specific context of each project:

| Analysis context | Recommended number of bands | Typical distance ranges |

|---|---|---|

| Ergonomic analysis | 3-4 bands | 0-50mm, 50-100mm, 100-200mm, >200mm |

| Assembly tolerance verification | 5-6 bands | 0-0.5mm, 0.5-1mm, 1-2mm, 2-5mm, 5-10mm, >10mm |

| Thermal analysis | 4-5 bands | 0-5mm, 5-15mm, 15-30mm, 30-50mm, >50mm |

The associated color code must also follow intuitive conventions, generally with red for critical distances and green for acceptable distances. This standardization facilitates rapid interpretation of results by all team members.

Step-by-step analysis process

A structured methodology allows for obtaining optimal results during band distance analysis:

- Model preparation: import and validation of geometry, correction of defects if necessary

- Selection of components to analyze: precise definition of the analysis perimeter

- Parameter configuration: definition of distance bands and colors

- Analysis execution: automated calculation of distances between components

- Results visualization: generation of colored volumes representing the bands

- Interpretation and validation: critical analysis of identified problematic areas

- Documentation and sharing: extraction of data for communication with teams

This methodical approach guarantees the reproducibility of analyses and facilitates their integration into modern concurrent engineering processes.

3DViewStation: optimal solution for band distance analysis

Faced with the technical challenges of distance analysis in CAD models, 3DViewStation stands out as a particularly suitable solution, combining performance, ease of use, and functional richness.

Technical capabilities of the platform

The 3DViewStation solution is based on a modern software architecture designed to meet the strictest requirements of industrial environments:

- High-performance 3D visualization engine based on DirectX

- Optimized loading technology allowing opening of assemblies of several gigabytes in seconds

- Sophisticated spatial analysis algorithms guaranteeing precision and speed

- Modern and intuitive user interface inspired by Office standards

- Scalable architecture available in Desktop, Web, VR, and mobile versions

These robust technical foundations allow 3DViewStation to efficiently process complex analysis scenarios on voluminous models, where other solutions reach their limits.

Specific band analysis functionalities

Band distance analysis in 3DViewStation offers a comprehensive set of specialized features:

- Flexible configuration of up to 6 simultaneous distance bands, fully customizable

- Automatic detection and visualization of the shortest distances between objects

- Automatic creation of dimensions at critical proximity points

- Generation of independent 3D geometries for each distance band

- Possibility to export results to various formats for documentation and sharing

- Instant analysis preserving interactivity even on complex models

This functional richness allows for covering all distance analysis scenarios, from simple verifications to complex analyses requiring detailed documentation.

Multi-format import capabilities

A major asset of 3DViewStation lies in its ability to natively process a wide range of CAD formats, eliminating interoperability problems:

| Category | Supported formats |

|---|---|

| Native CAD formats | CATIA V4/V5/V6/3DEXPERIENCE, NX, Creo, SolidWorks, Inventor |

| Neutral formats | STEP, IGES, JT, 3D PDF, 3MF, VRML |

| Visualization formats | OBJ, STL, COLLADA, glTF |

| Documentation formats | 3D PDF, HTML |

This versatility allows integrating 3DViewStation into any industrial ecosystem, without requiring potentially problematic prior conversions.

Performance with complex models

The management of large models constitutes a strong point of 3DViewStation, with impressive performance:

- Loading of 5 GB assemblies or 20,000 parts in seconds

- Maintenance of interactivity even during analysis calculations

- Optimized streaming technology for the Web version

- Intelligent memory management to avoid saturation

These capabilities allow engineering teams to work efficiently on complex projects without being limited by the performance of analysis tools.

Practical applications and case studies

Band distance analysis finds concrete applications in many industrial sectors, bringing tangible benefits in terms of quality, costs, and deadlines. Let's examine some representative use cases where this technology is transforming engineering practices.

Ergonomic analysis in the automotive industry

In automotive design, ergonomics is a critical factor that directly influences user experience and safety. Band distance analysis allows optimization of several aspects:

- Verification of distances between the driver and cockpit elements

- Analysis of accessibility of controls and storage areas

- Optimization of spaces for passenger comfort

- Validation of programmed deformation zones for passive safety

A European automotive manufacturer recently used this approach to optimize the ergonomics of the driver's position in a new model, reducing analysis time by 35% compared to traditional methods.

Space verification in architectural design

In the construction field, band distance analysis facilitates coordination between different trades:

- Early detection of conflicts between networks (electricity, plumbing, ventilation)

- Verification of maintenance spaces around technical equipment

- Validation of regulatory distances for accessibility

- Optimization of cable and piping routes

On a recent hospital center project, the systematic use of band analysis identified more than 200 potential conflicts before the start of construction, avoiding costly modifications during the construction phase.

Optimization of industrial piping layout

In complex industrial installations, optimization of piping networks represents a major challenge:

| Analysis type | Benefits obtained |

|---|---|

| Spacing between pipes | Reduction of thermal interference risks, optimization of insulation |

| Accessibility for maintenance | 40% improvement in intervention times on valves and fittings |

| Distances to supporting structures | Better distribution of supports, reduction of vibrations |

| Expansion zones | Prevention of excessive stress during thermal variations |

An oil refinery was able to reduce the total length of its piping by 15% by optimizing routing through band distance analysis, generating substantial savings in both materials and installation costs.

Best practices and analysis optimization

To fully benefit from band distance analysis, certain best practices deserve to be adopted. These recommendations, derived from advanced user experience, allow optimizing the analysis process and the quality of results obtained.

Optimal preparation of CAD models

The quality of the analysis directly depends on that of the models used. Adequate preparation is therefore essential:

- Preliminary cleaning of defective geometries (degenerated faces, free edges)

- Targeted simplification of areas not relevant to the analysis

- Verification of assembly coherence and constraints

- Clear hierarchical organization of components to facilitate selection

- Use of configurations or design states adapted to the analysis

This preliminary preparation not only improves the precision of results but also the overall performance of the analysis process, particularly important for large assemblies.

Recommended parametrization according to use cases

Each analysis context requires specific parameters to obtain relevant results:

| Analysis context | Recommended parameters | Special considerations |

|---|---|---|

| Mechanical tolerance analysis | 4-5 bands with logarithmic progression | High precision, calculation tolerance < 0.01mm |

| Accessibility verification | 3 bands with thresholds adapted to applicable standards | Integrate tool encumbrance volumes |

| Thermal analysis | Bands adapted to thermal influence distances | Consider material conductivity |

| Cable/pipe routing | Fine bands for critical passage areas | Include minimum bending radii |

These recommendations constitute a starting point, but it remains important to adapt the parameters to the specificities of each project and the internal standards of the company.

Tips for improving performance

Performance optimization allows maintaining productivity even on complex models:

- Limit analysis to truly relevant components rather than the complete assembly

- Use simplified representations (envelopes) for complex subassemblies

- Adapt calculation precision to the context: high precision is not always necessary

- Exploit parallel computation and multi-threading when available

- For recurring analyses, save configurations and reuse them

These optimizations can considerably reduce calculation times, for example from several hours to a few minutes for complex assemblies of several thousand components.

Effective collaborative workflows

Integration of band distance analysis into collaborative processes amplifies its value:

- Establish common analysis standards for the entire team (color codes, nomenclature)

- Systematically document the parameters used to guarantee reproducibility

- Share results in formats accessible to non-technical stakeholders

- Integrate analyses into design review milestones

- Set up a central repository for reference analyses

This collaborative approach transforms band distance analysis from a simple technical tool into a true vector of communication between the different disciplines involved in a project.

Documentation of results

The value of an analysis also lies in its ability to be effectively communicated:

- Generate standardized reports including analysis parameters and results

- Capture annotated views of identified critical areas

- Export results in shareable formats (3D PDF, HTML)

- Integrate quantitative metrics (band volumes, minimum distances)

- Maintain analysis history to track model evolution

Rigorous documentation not only allows communicating current results but also constitutes a valuable knowledge base for future projects and training of new collaborators.

Conclusion

Band distance analysis represents a significant advancement in the validation of CAD models, offering an intuitive visual approach that transforms complex data into immediately exploitable information. This methodology, combining mathematical rigor and visual representation, allows quickly identifying potential problems and optimizing designs even before the first prototyping phases.

Faced with challenges of interoperability and increasing complexity of digital models, solutions like 3DViewStation provide concrete answers thanks to their ability to natively process various CAD formats and efficiently analyze large assemblies. Band analysis features, combined with an intuitive interface, allow democratizing access to these advanced techniques beyond just CAD specialists.

Adoption of best practices in model preparation, analysis parametrization, and results documentation allows maximizing the added value of this approach. In an industrial context where pressure on deadlines and costs intensifies, band distance analysis establishes itself as a strategic tool to secure product quality while reducing development cycles.

As visualization and 3D analysis technologies continue to evolve, we can anticipate promising advances in this field, particularly integration with virtual and augmented reality, automation of analyses through artificial intelligence, and ever deeper integration into PLM processes. These evolutions will further strengthen the position of band distance analysis as a key technology in the arsenal of designers and engineers worldwide.